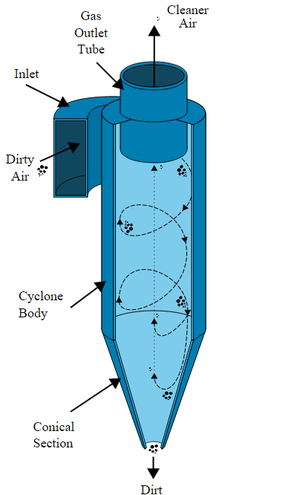

The Advantage Of Cyclone Separator

Cyclone separators are generally able to remove somewhere between 50-99% of all particulate matter in flue gas. How well the cyclone separators are actually able to remove this matter depends largely on particle size. If there is a large amount of lighter particulate matter, less of these par0ticles are able to be separated out. Because of this, cyclone separators work best on flue gases that contain large amounts of big particulate matter.

There are several advantages and disadvantages in using cyclone separators. First, cyclone separators are beneficial because they are not expensive to install or maintain, and they have no moving parts. This keeps maintenance and operating costs low. Second, the removed particulate matter is collected when dry, which makes it easier to dispose of. Finally, these units take up very little space. Although effective, there are also disadvantages in using cyclone separators. Mainly because the standard models are not able to collect particulate matter that is smaller than 10 micrometers effectively and the machines are unable to handle sticky or tacky materials well.

- The Features of Sintered Mesh Filter Compared with Traditional Filter

- How to Choose a Suitable Hydraulic Oil Filter

- Types of Hydraulic Oil Filter Element

- Filtration Material of Hydraulic Oil Filter

- The function of the inner and outer skeletons of the hydraulic oil filter element

- Which is better, Spiral Skeleton or Punch Plate Skeleton

- The difference between Carbon Steel and Stainless Steel

- The Difference Between Sintered Filter and Ordinary Filter