Features

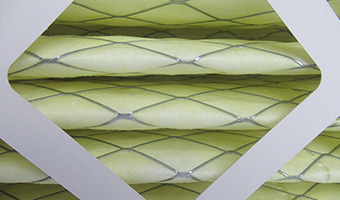

Filter material: synthetic fiber ,ultrafine polypropylene filter paper, glass fiber filter paper

Outer frame: paper,plastic, galvanized iron sheet

Separator: hot melt adhesive

Sealant: polyurethane

Operating temperature: -20~80 degrees

Humidity: 80% or less

Efficiency: F6 / F7 F8 / F9 / H10

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)